| Availability: | |

|---|---|

| Quantity: | |

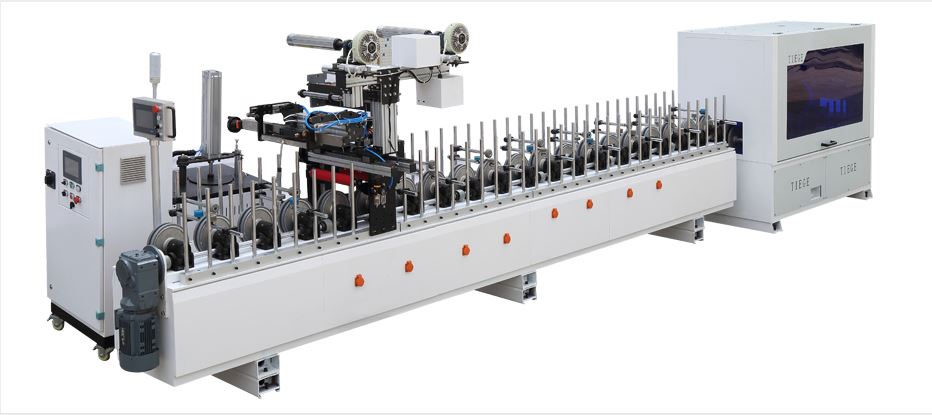

1) Equipped with 5-gallon open mode glue melting system.

2) The rubber knife can be opened and closed separately for both sides.

3) Vertical pole debugging line type.

4) The single side pole can be moved, and the electric moving in and out is controlled.

5) The electrical components, PLC and touch screen are made in China, while the pneumatic components are made of Adec,

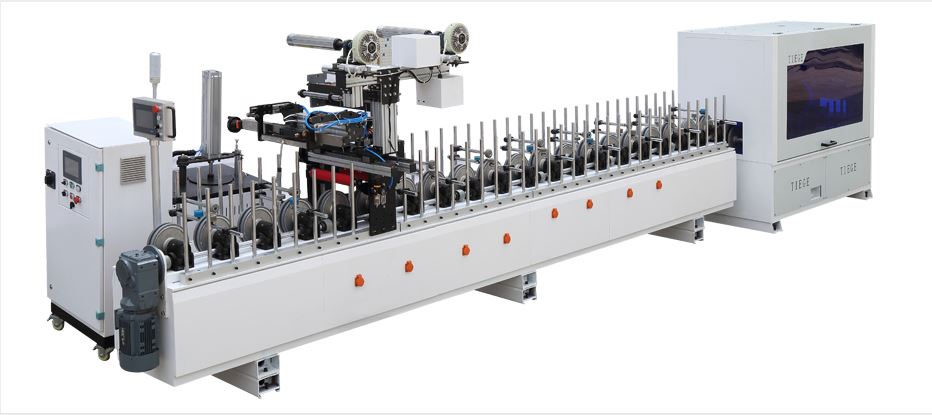

Mechanical appearance (based on the current design): touch screen display, PLC system operation.

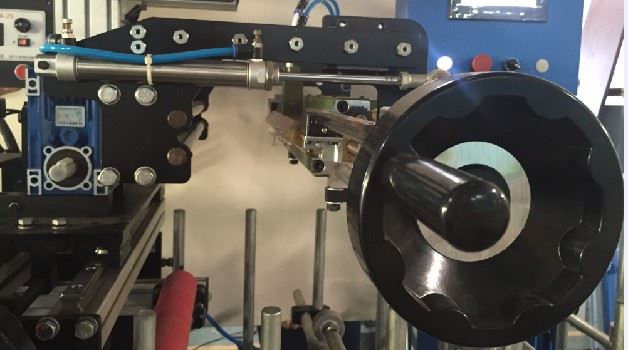

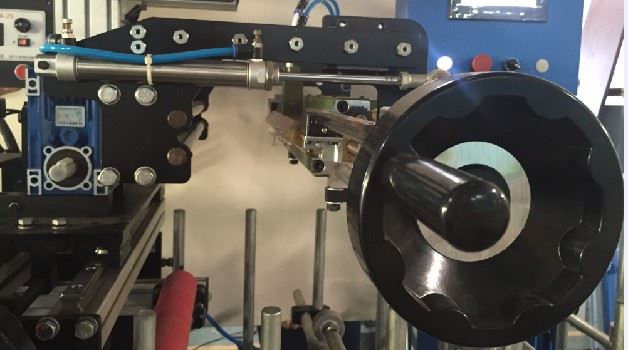

6) The transmission mode is drum box.

1) It can be coated on any linear material. It is easy to adjust the width from the middle to both sides;After the work is finished, it is necessary to put the split together, put the digital display on the glue knife, adjust it according to the film width, and seal it with transparent glue when off duty.

2) The whole knife base is butterfly type screw rod, which can be adjusted and moved. Fine adjustment can be made at will during the production process to improve the accuracy of coating mouth and fabric.

2. The fixed rubber knife is rotated by the reducer. When the glue amount is adjusted slightly, the angle of the glue knife can be tilted to make the glue amount more uniform.When the fabric is thin, it can reduce the resistance and prevent material breakage.

3. The height of base material is adjusted by screw rod, which is convenient and quick.

The brake is a magnetic powder tension controller with stable force control. The magnetic powder brake is 2.5kg.

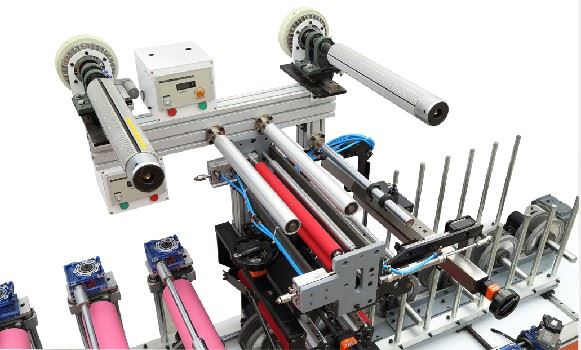

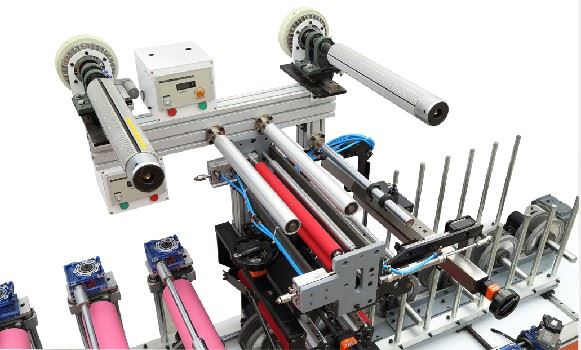

4. Double roll film releasing device.

5. Glue melting system and mechanical wire docking: aviation socket is used, easy to use and operate.

150 diameter silicon rubber rollers are used to press the plane pressing together. The pressure of each pressing roller is adjusted separately to prevent the material from deforming and the pressure is not in place. The adjustment and lifting is the lifting of drum and pole, which will not cause imbalance.

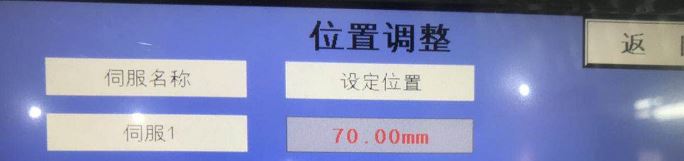

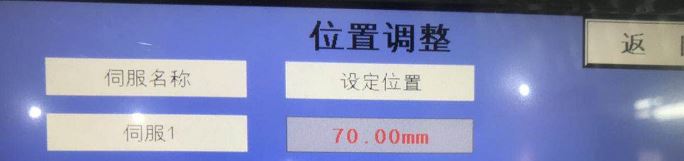

Servo control, data input automatic adjustment, servo electronic drum reducer, accurate and reliable, digital input, convenient and fast, the whole machine in place to adjust the width at one time.

The single butterfly guide channel moves synchronously, and four drum motors are driven by servo motor, which is accurate.

The transmission wheel is adjusted. When the two sides are adjusted, the driving wheel is adjusted at the same time.

The equipment is suitable for 5-gallon barreled pur hot melt adhesive

Precision metering pump glue, independent pressure control system

Multi section temperature / motor speed curve setting, manual / automatic control

The upper and lower temperature alarm device, temperature sensor damage alarm, heater damage alarm

Motor / pump locked rotor protection, intelligent fault location and other functions

Inch color touch screen, PLC control system

0.75Kw (a motor is installed above the rubber bucket to give the power needed by the lower gear pump rubber, with a single machine power of 0.75Kw/ set)

18Kw (60 heating pipes are placed in the gear pump to provide the heat required for melting PUR glue, and the heating pipe power is 0.3Kw/ piece)

1) Equipped with 5-gallon open mode glue melting system.

2) The rubber knife can be opened and closed separately for both sides.

3) Vertical pole debugging line type.

4) The single side pole can be moved, and the electric moving in and out is controlled.

5) The electrical components, PLC and touch screen are made in China, while the pneumatic components are made of Adec,

Mechanical appearance (based on the current design): touch screen display, PLC system operation.

6) The transmission mode is drum box.

1) It can be coated on any linear material. It is easy to adjust the width from the middle to both sides;After the work is finished, it is necessary to put the split together, put the digital display on the glue knife, adjust it according to the film width, and seal it with transparent glue when off duty.

2) The whole knife base is butterfly type screw rod, which can be adjusted and moved. Fine adjustment can be made at will during the production process to improve the accuracy of coating mouth and fabric.

2. The fixed rubber knife is rotated by the reducer. When the glue amount is adjusted slightly, the angle of the glue knife can be tilted to make the glue amount more uniform.When the fabric is thin, it can reduce the resistance and prevent material breakage.

3. The height of base material is adjusted by screw rod, which is convenient and quick.

The brake is a magnetic powder tension controller with stable force control. The magnetic powder brake is 2.5kg.

4. Double roll film releasing device.

5. Glue melting system and mechanical wire docking: aviation socket is used, easy to use and operate.

150 diameter silicon rubber rollers are used to press the plane pressing together. The pressure of each pressing roller is adjusted separately to prevent the material from deforming and the pressure is not in place. The adjustment and lifting is the lifting of drum and pole, which will not cause imbalance.

Servo control, data input automatic adjustment, servo electronic drum reducer, accurate and reliable, digital input, convenient and fast, the whole machine in place to adjust the width at one time.

The single butterfly guide channel moves synchronously, and four drum motors are driven by servo motor, which is accurate.

The transmission wheel is adjusted. When the two sides are adjusted, the driving wheel is adjusted at the same time.

The equipment is suitable for 5-gallon barreled pur hot melt adhesive

Precision metering pump glue, independent pressure control system

Multi section temperature / motor speed curve setting, manual / automatic control

The upper and lower temperature alarm device, temperature sensor damage alarm, heater damage alarm

Motor / pump locked rotor protection, intelligent fault location and other functions

Inch color touch screen, PLC control system

0.75Kw (a motor is installed above the rubber bucket to give the power needed by the lower gear pump rubber, with a single machine power of 0.75Kw/ set)

18Kw (60 heating pipes are placed in the gear pump to provide the heat required for melting PUR glue, and the heating pipe power is 0.3Kw/ piece)

Copyright © Guangzhou Tiege Woodworking Machinery Co., Ltd. All Rights Reserved.| Sitemap