| Availability: | |

|---|---|

| Quantity: | |

Main Profile width | 50 -180mm |

Main profile thickness | 10 -40mm |

Side profile width | 20 -60mm |

Side profile thickness | 5 -18mm |

Main infeed speed | 5 -30m/min |

Working process length | 1500-3000mm |

Infeed motor power | 3Kw |

Total power | 5Kw |

Volage | 380V |

Machine size | 6000x1600x1700mm |

Machine weight | 2000kg |

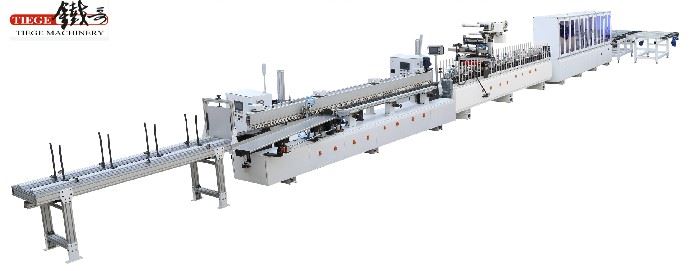

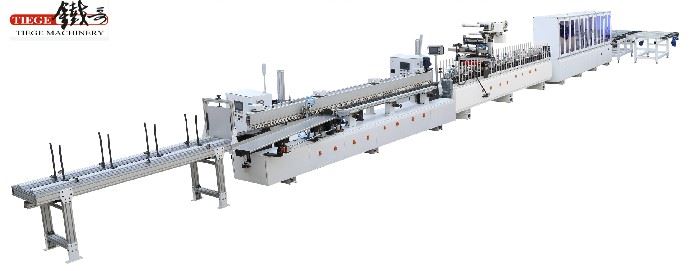

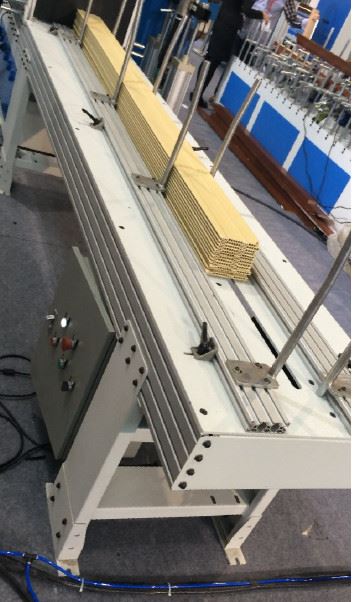

This machine is specialzie in make the „L“ shape profile ,model is FMF-L(normalyis righ sides direction.),and it is can finish the “L“ joint,the joint profiles can go to profile wrapping machine to finish wrapping film.

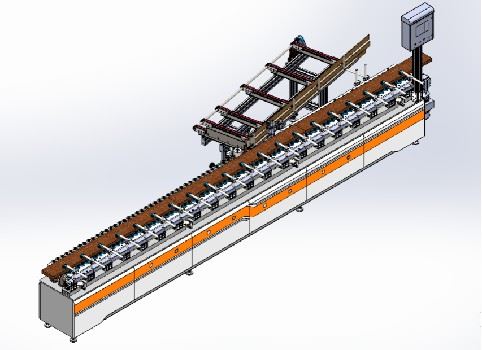

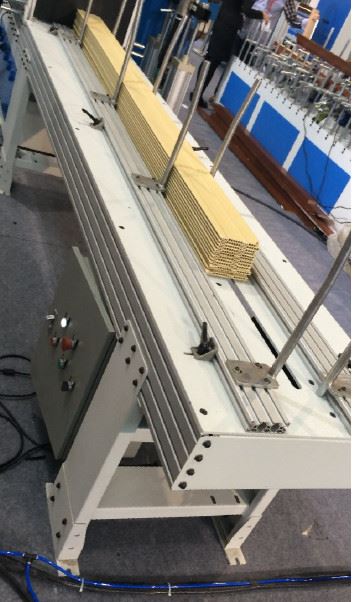

The frame is composed of a solid steel structure and castings, all of which are processed and produced by the machining center, and the structure is stable.

-High-speed precision transmission system, 20 groups of transmission wheels quickly adjust the opening and closing device, and quicklyadjust the feeding width according to the width of the material;

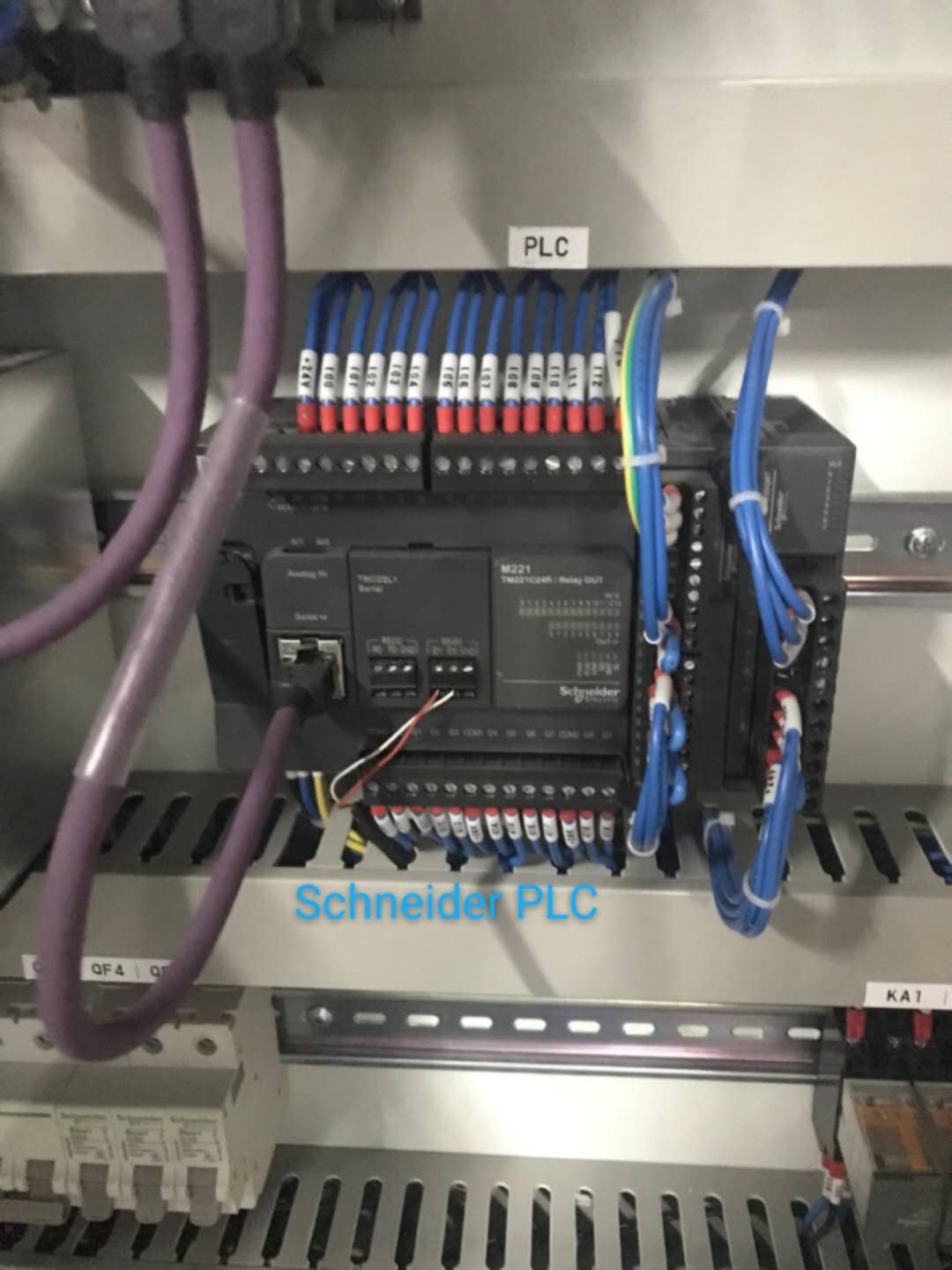

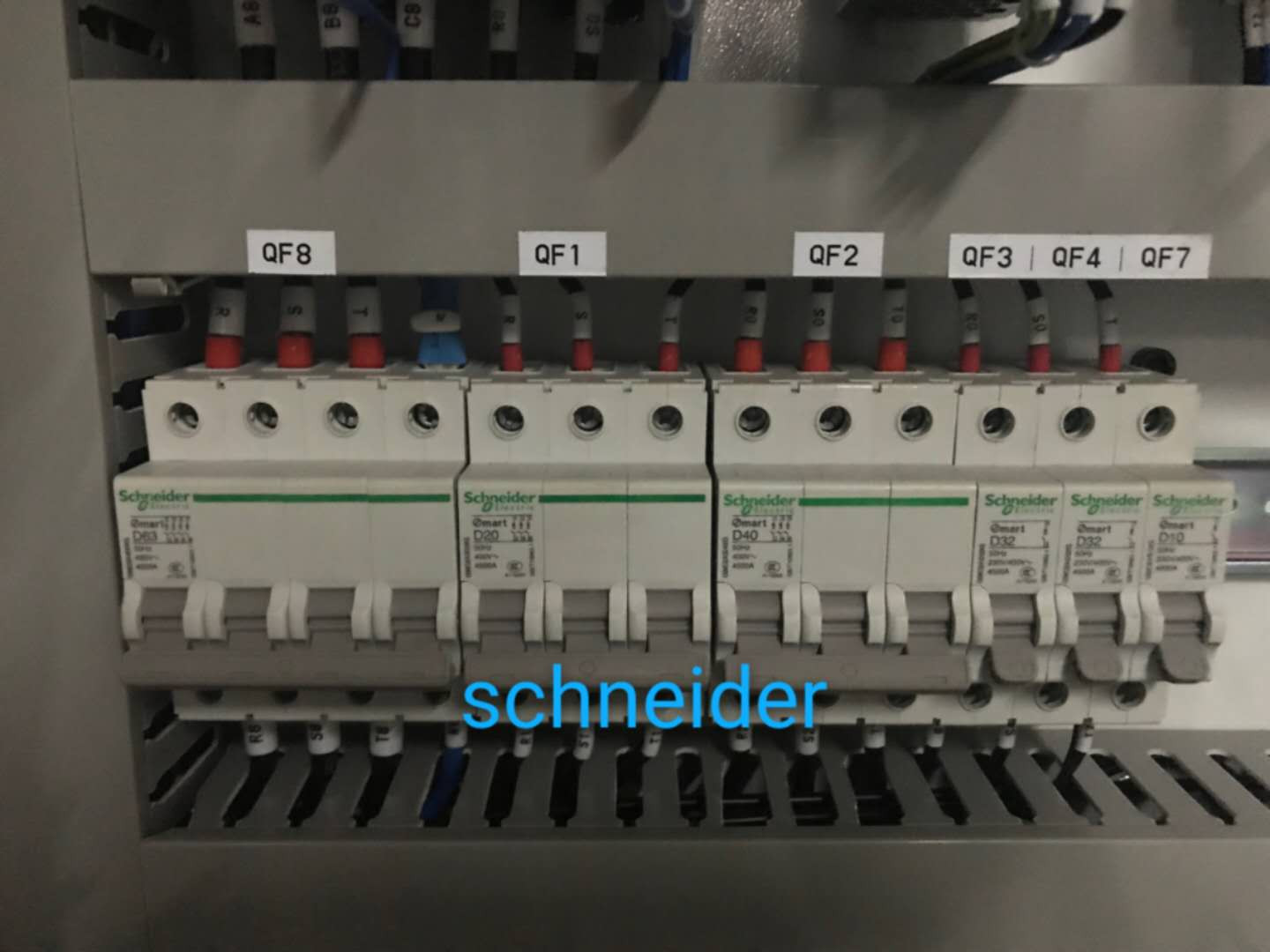

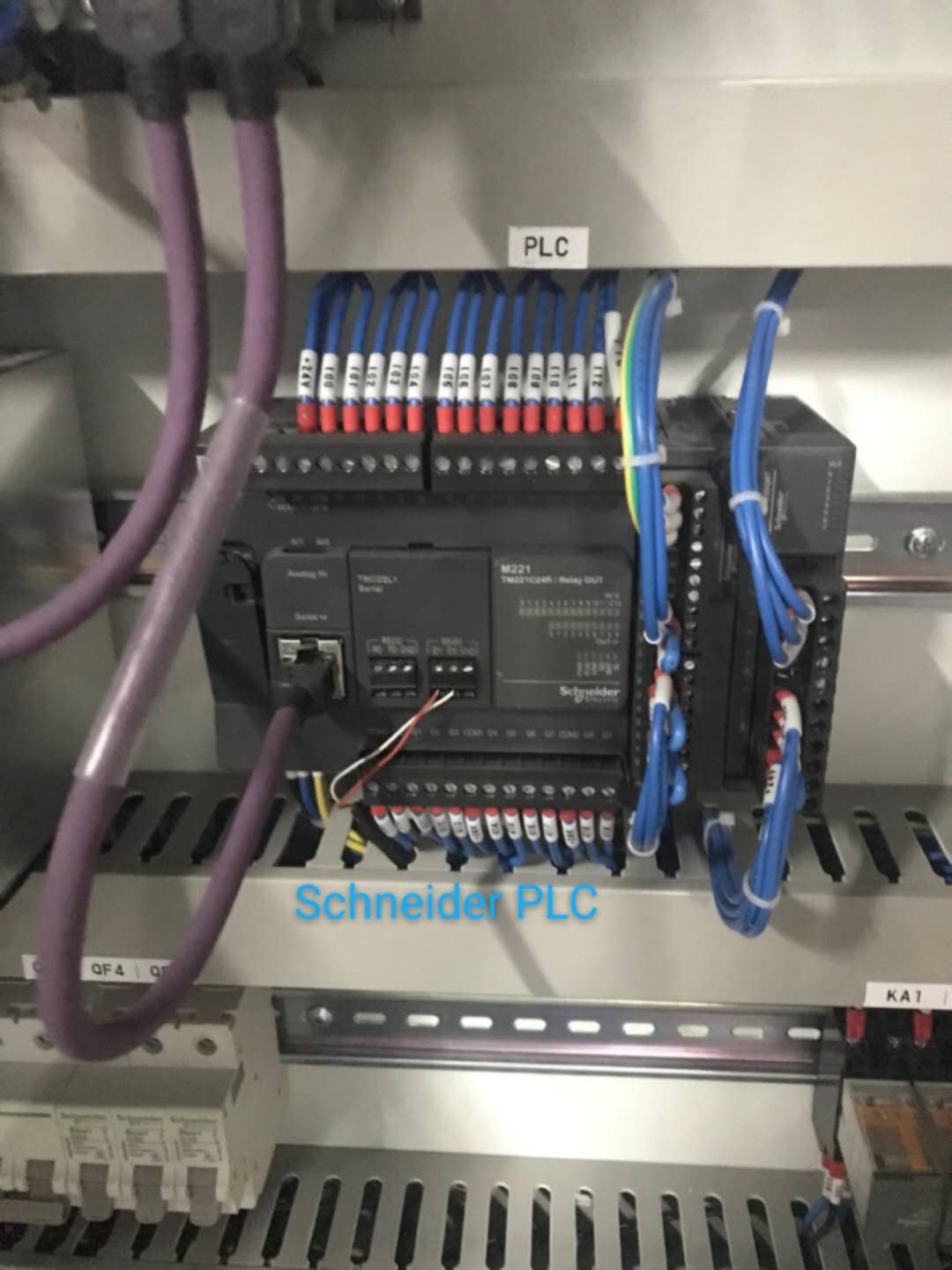

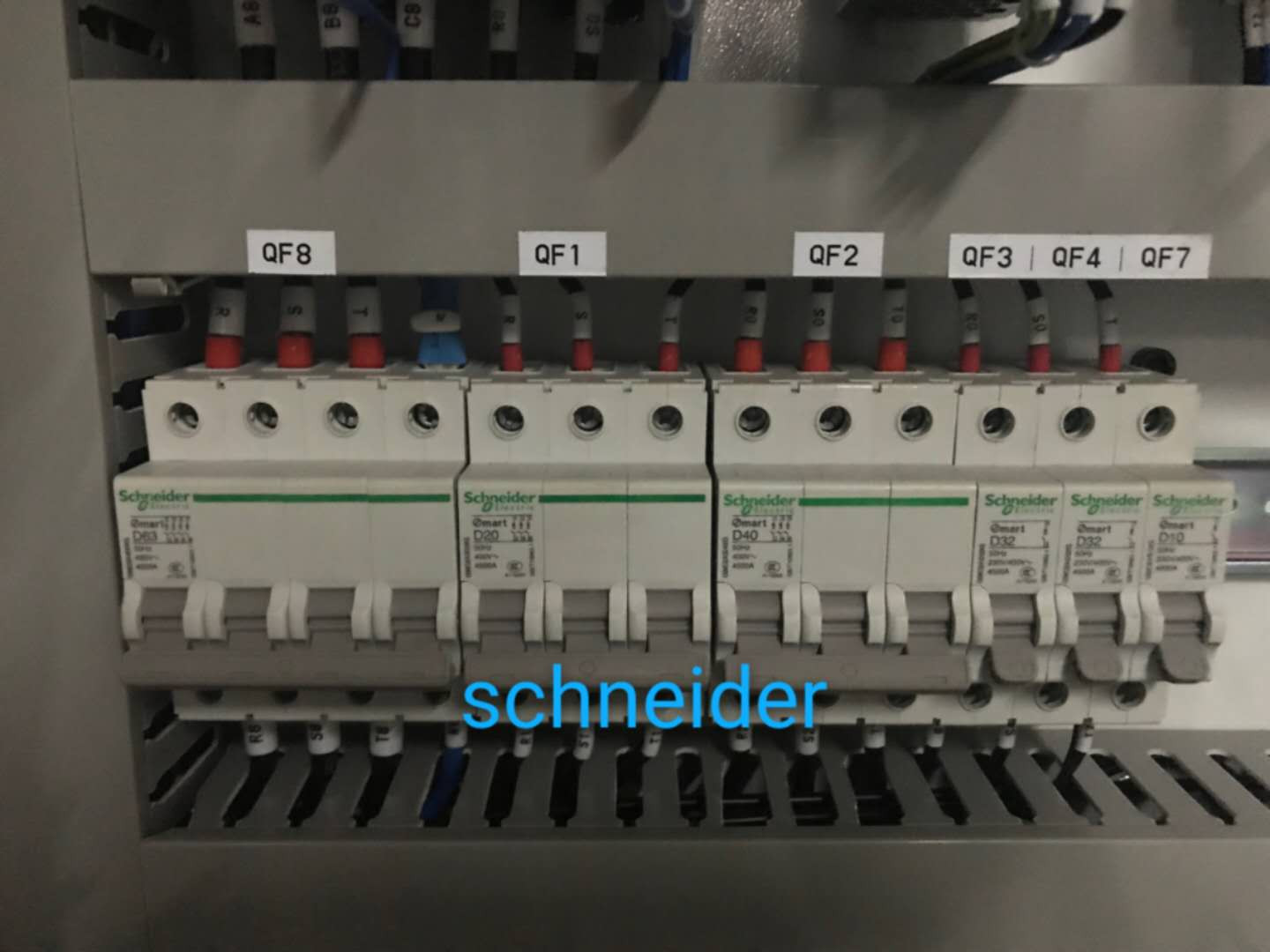

-The speed of the host is controlled by frequency converter, which is connected with the melt system by PLC and touch screen to form an automatic control, and the electrical components are Schneider.

-The workpiece feeding system is composed of a special high-precision chain. The conveyor chain block is assembled by quenching the round bar and the needle bearing. It is also equipped with round double-end sliding shoes and high friction surface rubber covered chain block.

-The upper pressure bar is installed on the shaft and used in conjunction with the conveyor chain. It is equipped with a rubber pressure wheel. The pressure wheel is mechanically electric lift. It is also suitable for processing small-sized workpieces.

-Adjustable speed of workpiece feed speed, 5-30 m/min.

- 5 Galon PUR glue melting system

- One glue hose and one PLC control Glue injector

- Glue type: Scrap glue ,the glue thickness and height can be adjust

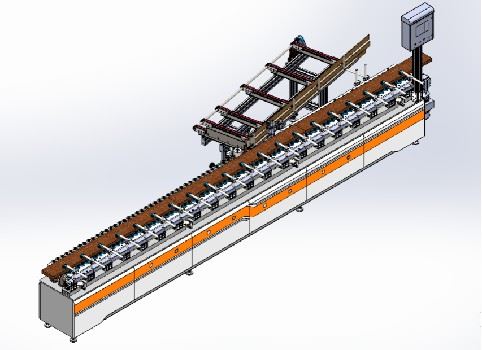

- L shape ,auto pusher ,600MM thickness capacity

- The side profile infeed control by pusher signal,working table is 2.5 meter.

- PLC control all process.

-The machine is specialize in making L shape ,the speed is 3-30m/min.

The machine use the PUR glue .

a. Power of glue pump:7.8KW(One motor at above of glue drum and provide the power of the glue gear)

b. Heating power:7.2KW,It is have 24 pieces heating tube and provide power to melting glue.The power of heating tube is 0.3KW/pieces

c. Total power:15Kw

d. Gear pump:15grams/r

e. Glue:0-35Kg/h

f. Voltage:380V

g. Air pressure:6 Bar

h. Motor run speed:0.5-60r/min

i. dimension:1085*600*1214mm

j. weight:360Kg

Auto pusher | TG-3000L |

Stack heighth | 300mm |

Infeed width | 300mm |

Motor | 0.37kw |

Induction feed | limit switch |

Speed | 5-40m/min(invert control) |

Working action | Side profile infeed |

Main Profile width | 50 -180mm |

Main profile thickness | 10 -40mm |

Side profile width | 20 -60mm |

Side profile thickness | 5 -18mm |

Main infeed speed | 5 -30m/min |

Working process length | 1500-3000mm |

Infeed motor power | 3Kw |

Total power | 5Kw |

Volage | 380V |

Machine size | 6000x1600x1700mm |

Machine weight | 2000kg |

This machine is specialzie in make the „L“ shape profile ,model is FMF-L(normalyis righ sides direction.),and it is can finish the “L“ joint,the joint profiles can go to profile wrapping machine to finish wrapping film.

The frame is composed of a solid steel structure and castings, all of which are processed and produced by the machining center, and the structure is stable.

-High-speed precision transmission system, 20 groups of transmission wheels quickly adjust the opening and closing device, and quicklyadjust the feeding width according to the width of the material;

-The speed of the host is controlled by frequency converter, which is connected with the melt system by PLC and touch screen to form an automatic control, and the electrical components are Schneider.

-The workpiece feeding system is composed of a special high-precision chain. The conveyor chain block is assembled by quenching the round bar and the needle bearing. It is also equipped with round double-end sliding shoes and high friction surface rubber covered chain block.

-The upper pressure bar is installed on the shaft and used in conjunction with the conveyor chain. It is equipped with a rubber pressure wheel. The pressure wheel is mechanically electric lift. It is also suitable for processing small-sized workpieces.

-Adjustable speed of workpiece feed speed, 5-30 m/min.

- 5 Galon PUR glue melting system

- One glue hose and one PLC control Glue injector

- Glue type: Scrap glue ,the glue thickness and height can be adjust

- L shape ,auto pusher ,600MM thickness capacity

- The side profile infeed control by pusher signal,working table is 2.5 meter.

- PLC control all process.

-The machine is specialize in making L shape ,the speed is 3-30m/min.

The machine use the PUR glue .

a. Power of glue pump:7.8KW(One motor at above of glue drum and provide the power of the glue gear)

b. Heating power:7.2KW,It is have 24 pieces heating tube and provide power to melting glue.The power of heating tube is 0.3KW/pieces

c. Total power:15Kw

d. Gear pump:15grams/r

e. Glue:0-35Kg/h

f. Voltage:380V

g. Air pressure:6 Bar

h. Motor run speed:0.5-60r/min

i. dimension:1085*600*1214mm

j. weight:360Kg

Auto pusher | TG-3000L |

Stack heighth | 300mm |

Infeed width | 300mm |

Motor | 0.37kw |

Induction feed | limit switch |

Speed | 5-40m/min(invert control) |

Working action | Side profile infeed |

Copyright © Guangzhou Tiege Woodworking Machinery Co., Ltd. All Rights Reserved.| Sitemap