| Availability: | |

|---|---|

| Quantity: | |

-The transmission of the machine base is unified by a 5.5KW transmission motor, and the speed ratio of each part is matched and adjusted by the ratio of the reducer and the sprocket.

-Conveyor base is tailor-welded by square pass and steel plate. The structure is firm. The surface level of the base is balanced by the grinding field to ensure the working level of the whole machine.

-The conveying roller is made of precision drawn seamless steel tube covered with rubber, which has small runout, stable conveying, and does not cause friction and bumps on the surface of the product.

-The length of the roller body is 1350mm, and the conveying row is driven by a "8"-shaped flat belt, which is stable in transmission, small in vibration and no noise;

-The conveyor rollers are arranged in an oblique row, and the plates are always leaning against the stop during the conveying process until the output plates are in a straight line, effectively reducing the occurrence of waste due to the offset of the plate conveying process.

-The dust removal machine adopts a wool sweeping round roller to remove dust. The rotation of the brush roller is driven by a VF30F-5-6B14 reducer and a 0.25kw motor. It is driven independently and connected to a 100MM diameter dust removal tube.

-Coating rubber roller with natural rubber diameter of Φ190, the rubber roller hardness is 65 degrees. The transmission method adopts gear transmission; the upper roller adopts turbine lifting, and the lifting height can be displayed digitally. The rubber roller is controlled by the rubber roller with flanges at both ends, and the rubber copper plate is precisely cut to ensure that the glue does not leak when working.

-The rubber-coated steel roller is a stainless steel roller with a diameter of 145.

-The 1.5kw motor is used to drive the roller independently. The glue roller and the stainless steel roller are independently rotated by one-way bearings. The rotation is stable and the glue is evenly applied. During the rotation, there will be no rack horizontal lines driven by the chain;

-The inner width of the glue applicator is 1510mm, the effective working width of the glued rubber roller and the glued steel roller is 1350mm, the effective working width of the bottom roller is 1300, and the bottom roller is narrower than the surface roller to prevent the sticking of materials within 1mm When the pressure is applied, the two rollers are in contact, causing the bottom roller to stick.

4.Four groups of film sticking machine with pvc hoist 500KG.

-The first and second sets of laminating rollers have a diameter of 190 natural rubber rollers, the second set can be used to stick protective films, and the third, fourth, fifth, and sixth sets are heating rollers with a diam.eter of 190.

-Pneumatic lifting, hand-operated pot wheel and pot rod, with display scale.

-Equipped with paper cutter, servo motor rotates the cutter.

-The film releasing device is an air shaft, equipped with 2.5 kg magnetic powder brake, which is stable.

-PVC small heating roller, the heating roller is 1kw electric heating, with ribbed loose paper function.

PVC hoist

5.The electrical components are Schneider, and the operation interface is a touch screen.

6.Discharge conveyor

Maximum transport width: 1300mm and 1100MM

Maximum transport length: 3000mm

Working height: 950mm

Transport speed:5-22m/min (frequency conversion adjustment)

Installed power : 0.75kw

-The conveyor rack is tailor-welded with 80*80 square tubes, and the structure is firm and reliable.

-The conveying roller is made of precision drawn seamless steel tube covered with rubber, which has small runout, stable conveying, and does not cause friction and bumps on the surface of the product;

-The length of the roller body is 1350mm, and the conveying row is driven by a "8"-shaped flat belt, which is stable in transmission, small in vibration and no noise;

-Each group of conveying rows is driven by RV63-75-speed Borel turbine worm reducer, 0.75kw motor, and frequency conversion speed; each group speed is increased in proportion to effectively control the distance between the plates;

-The conveying rollers are arranged in an oblique row, and the plates are always leaning up against the stop during the conveying process until the output plates are in a straight line.

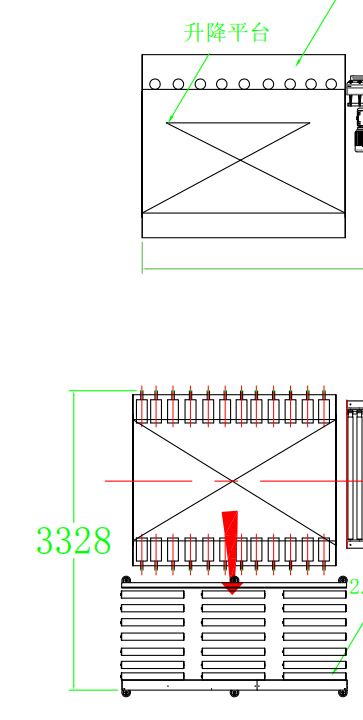

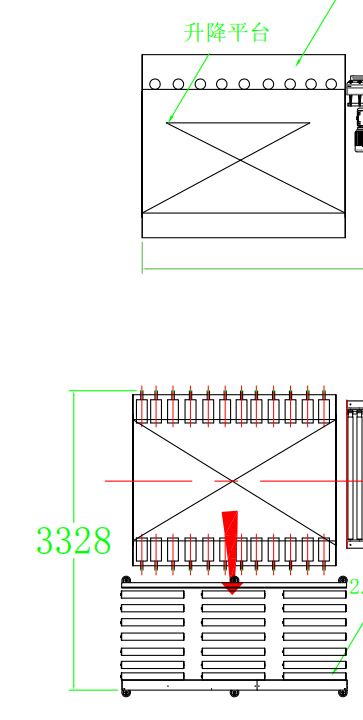

①lift table with roller

- Max,heighth :2500mm

- min,heighth :1400mm

- stroke :1150mm

- size :1150*2100mm

- motor power :2.2kw

- working weight :2TONS

Pusher

-The transmission of the machine base is unified by a 5.5KW transmission motor, and the speed ratio of each part is matched and adjusted by the ratio of the reducer and the sprocket.

-Conveyor base is tailor-welded by square pass and steel plate. The structure is firm. The surface level of the base is balanced by the grinding field to ensure the working level of the whole machine.

-The conveying roller is made of precision drawn seamless steel tube covered with rubber, which has small runout, stable conveying, and does not cause friction and bumps on the surface of the product.

-The length of the roller body is 1350mm, and the conveying row is driven by a "8"-shaped flat belt, which is stable in transmission, small in vibration and no noise;

-The conveyor rollers are arranged in an oblique row, and the plates are always leaning against the stop during the conveying process until the output plates are in a straight line, effectively reducing the occurrence of waste due to the offset of the plate conveying process.

-The dust removal machine adopts a wool sweeping round roller to remove dust. The rotation of the brush roller is driven by a VF30F-5-6B14 reducer and a 0.25kw motor. It is driven independently and connected to a 100MM diameter dust removal tube.

-Coating rubber roller with natural rubber diameter of Φ190, the rubber roller hardness is 65 degrees. The transmission method adopts gear transmission; the upper roller adopts turbine lifting, and the lifting height can be displayed digitally. The rubber roller is controlled by the rubber roller with flanges at both ends, and the rubber copper plate is precisely cut to ensure that the glue does not leak when working.

-The rubber-coated steel roller is a stainless steel roller with a diameter of 145.

-The 1.5kw motor is used to drive the roller independently. The glue roller and the stainless steel roller are independently rotated by one-way bearings. The rotation is stable and the glue is evenly applied. During the rotation, there will be no rack horizontal lines driven by the chain;

-The inner width of the glue applicator is 1510mm, the effective working width of the glued rubber roller and the glued steel roller is 1350mm, the effective working width of the bottom roller is 1300, and the bottom roller is narrower than the surface roller to prevent the sticking of materials within 1mm When the pressure is applied, the two rollers are in contact, causing the bottom roller to stick.

4.Four groups of film sticking machine with pvc hoist 500KG.

-The first and second sets of laminating rollers have a diameter of 190 natural rubber rollers, the second set can be used to stick protective films, and the third, fourth, fifth, and sixth sets are heating rollers with a diam.eter of 190.

-Pneumatic lifting, hand-operated pot wheel and pot rod, with display scale.

-Equipped with paper cutter, servo motor rotates the cutter.

-The film releasing device is an air shaft, equipped with 2.5 kg magnetic powder brake, which is stable.

-PVC small heating roller, the heating roller is 1kw electric heating, with ribbed loose paper function.

PVC hoist

5.The electrical components are Schneider, and the operation interface is a touch screen.

6.Discharge conveyor

Maximum transport width: 1300mm and 1100MM

Maximum transport length: 3000mm

Working height: 950mm

Transport speed:5-22m/min (frequency conversion adjustment)

Installed power : 0.75kw

-The conveyor rack is tailor-welded with 80*80 square tubes, and the structure is firm and reliable.

-The conveying roller is made of precision drawn seamless steel tube covered with rubber, which has small runout, stable conveying, and does not cause friction and bumps on the surface of the product;

-The length of the roller body is 1350mm, and the conveying row is driven by a "8"-shaped flat belt, which is stable in transmission, small in vibration and no noise;

-Each group of conveying rows is driven by RV63-75-speed Borel turbine worm reducer, 0.75kw motor, and frequency conversion speed; each group speed is increased in proportion to effectively control the distance between the plates;

-The conveying rollers are arranged in an oblique row, and the plates are always leaning up against the stop during the conveying process until the output plates are in a straight line.

①lift table with roller

- Max,heighth :2500mm

- min,heighth :1400mm

- stroke :1150mm

- size :1150*2100mm

- motor power :2.2kw

- working weight :2TONS

Pusher

Copyright © Guangzhou Tiege Woodworking Machinery Co., Ltd. All Rights Reserved.| Sitemap