Views: 124 Author: Site Editor Publish Time: 2023-06-20 Origin: Site

The woodworking industry has undergone a significant transformation over the years, thanks to the arrival of automation in various operational processes. One of the most significant areas that have been impacted by this innovation is veneer wrapping, where automated technology is helping to boost efficiency, enhance quality control, and reduce costs. In this article, we'll delve deeper into the benefits of them in woodworking and explore how it works.

It is a process that involves covering a base material with a thin sheet of veneer. The base material is typically made of a less expensive wood, while the veneer is made of a more expensive and aesthetically appealing wood. The process is used to create decorative surfaces for furniture, cabinetry, and other wooden items.

Traditionally, veneer wrapping was done manually, which was a time-consuming and labor-intensive process. It involved gluing the veneer to the base material and then trimming off the excess. However, with the automation of them, manufacturers can now achieve greater speed, precision, and consistency in the process.

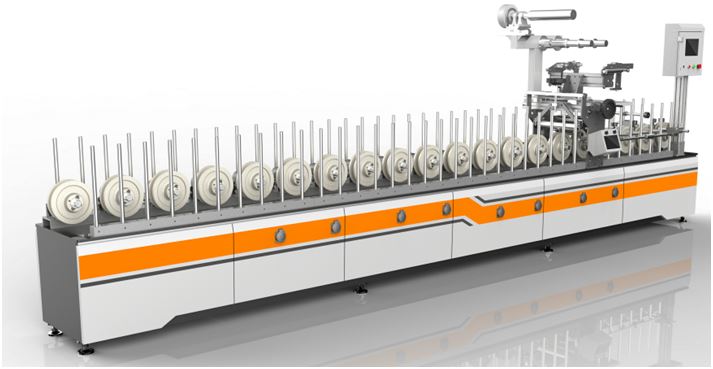

They systems vary depending on the manufacturer and application. However, the key components of a standard machine include a feed system, which moves the base material through the machine, a glue application system, which applies adhesive to the veneer, a veneer cutter, which trims the excess veneer, and a pressing system, which applies pressure to the veneer and base material to ensure a strong bond.

The machine operates by first feeding the base material through the system. The glue is then applied to the veneer, which is then cut to size and placed onto the base material. The pressing system is then activated, using a combination of pressure and heat to ensure a strong bond.

1. Increased Efficiency

They systems are much faster than manual processes, enabling manufacturers to produce more products in less time. This increased efficiency is critical for meeting customer demands, especially in industries where large-scale production is required.

2. Improved Quality Control

Automated systems provide greater precision and consistency in the veneer wrapping process. This results in a higher quality end-product, with fewer defects and more uniformity. With automated veneer wrapping, manufacturers have better control over product quality, ensuring that their products meet their customers' expectations.

3. Cost Savings

They can help reduce costs in several ways. Firstly, the increased efficiency allows manufacturers to produce more products, reducing the cost per unit. Additionally, the reduced labor requirements also help cut labor costs, while the improved quality control means that there are fewer product defects, reducing the cost of rework and scrap.

4. Improved Safety

They systems have safety features built into them, including guards and sensors that detect and prevent accidents. This helps to reduce workplace injuries, making it a safer process for workers.

Automated veneer packaging example

Here we recommend you the company that has developed an automatic veneer packaging system for the woodworking industry. These systems include:

1. profile-wrappingmachine.com

profile-wrappingmachine.com provides a variety of automatic veneer packaging systems, including our professional production of PUR high-gloss pvc film laminating machine, drawer panel winding machine line, PUR profile winding machine, PUR edge banding machine, PUR honeycomb door laminating line, PUR steel lamination pvc machine, PUR laminated wire, automatic sticker machine, frame assembly machine, CNC boring and tenoning machine.

It is suitable for surface decoration of various plates and profiles. And carry out product research and development, and provide effective solutions. Professional --- We have many years of experience in researching adhesives. We can provide various items for our clients. We have a very deep understanding of adhesives. We not only sell machines, but also provide usage tips and services.

Copyright © Guangzhou Tiege Woodworking Machinery Co., Ltd. All Rights Reserved.| Sitemap