| Availability: | |

|---|---|

| Quantity: | |

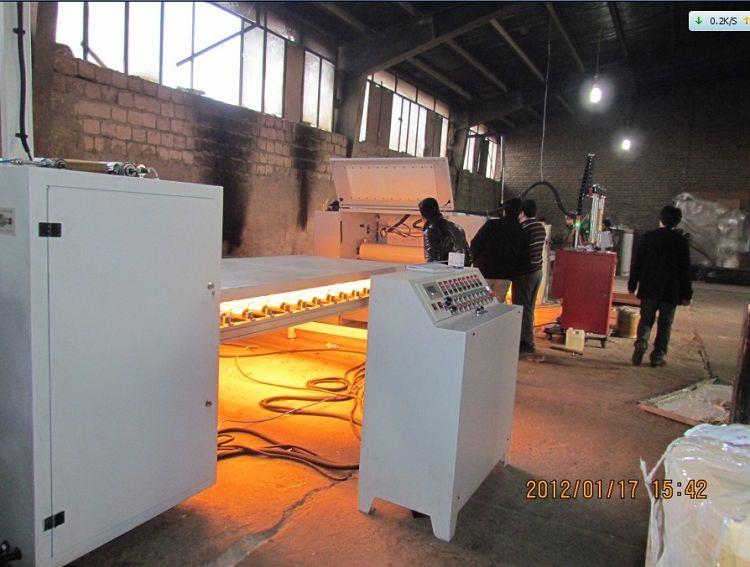

PUR roller lamination line is to laminate different material on mdf or particleboard etc.It uses PUR hot meling glue.The laminated board has high adhesion,weather resistance,waterproof,environmental protection and so on.The suitable It is suitable for high glossy sheet laminating,composite floor,hpl laminating,etc.

Particleboard,MDF,plywood,high polymer plastic board ,metal aluminum plate,foam board and other sheet;laminating material:PET high light film,PVC,wood grain paper ,HPL ,CPL ANTI-FIRE THIN film,acrylic,aluminum FILM and so on sheets or rolls.Glue: PUR reactive hot melting glue.

1)transport platform(one or two people to send board,depending on the size of the board,weight)

2)single-sIde glue spreader(using anilox steel roller control glue,silicone rubber roller coating,glue volume adjustable,uniform coating)

3)manual composite platform(operators put laminating materials on raw board after glue spreading and send to continuous roller pressing)

4)roller press

5)outfeeding platform(manual lifting board)

1220mm * 2440mm

5-40mm

1-20m/min

60 KW

15 M(long) x 2M(wide) x 1.8M(high)

The whole machine frequency control(all parameters to the final design)

PUR roller lamination line is to laminate different material on mdf or particleboard etc.It uses PUR hot meling glue.The laminated board has high adhesion,weather resistance,waterproof,environmental protection and so on.The suitable It is suitable for high glossy sheet laminating,composite floor,hpl laminating,etc.

Particleboard,MDF,plywood,high polymer plastic board ,metal aluminum plate,foam board and other sheet;laminating material:PET high light film,PVC,wood grain paper ,HPL ,CPL ANTI-FIRE THIN film,acrylic,aluminum FILM and so on sheets or rolls.Glue: PUR reactive hot melting glue.

1)transport platform(one or two people to send board,depending on the size of the board,weight)

2)single-sIde glue spreader(using anilox steel roller control glue,silicone rubber roller coating,glue volume adjustable,uniform coating)

3)manual composite platform(operators put laminating materials on raw board after glue spreading and send to continuous roller pressing)

4)roller press

5)outfeeding platform(manual lifting board)

1220mm * 2440mm

5-40mm

1-20m/min

60 KW

15 M(long) x 2M(wide) x 1.8M(high)

The whole machine frequency control(all parameters to the final design)

Copyright © Guangzhou Tiege Woodworking Machinery Co., Ltd. All Rights Reserved.| Sitemap