Views: 8658 Author: Site Editor Publish Time: 2020-09-21 Origin: Site

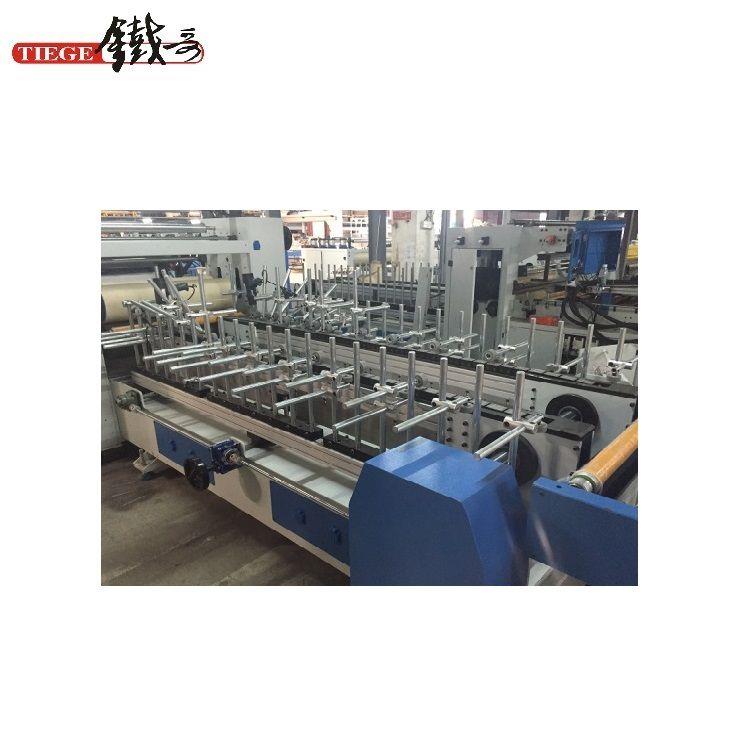

The working principle of pur laminating machine: The working principle of automatic coating machine for screen printing is the same, but the performance of pur laminating machine varies according to different models and different manufacturers.The pur laminating machine has a device that clamps the frame on the vertical frame.The front and rear of the screen area is a horizontal pur laminating machine mechanism consisting of a coating tank and mechanical or pneumatic components that control the angle and pressure of the coating tank.

1.Pur laminating machine uses 3 variable frequency motor control.

2.The discharging rack mode is electric turning double station, and the magnetic powder automatic tension control is adopted.

3.The netting coating method, the coating scraper shaft adopts the heavy-duty double-axis machine to independently swim, the scraper conditioning method is manual pneumatic, the angle is carelable, the coating amount depends on the anilox roller eye line, different coating The amount of cloth can be changed to the anilox roller of different eye lines.

4.For the pur laminating machine, the average coating is 1 set of the rubber roller, which is controlled by the motor inverter.

5.The oven is independently controlled by 16 meters and 6 sections.The heating is heated by heat transfer oil.The hot air enters the monotonous and fragmented, adjustable internal circulation suction and exhaust installation.The wind in the inlet and outlet is weak and monotonous.

6.The inner roller of the pur laminating machine is automatically synchronized with the main engine.The transmission adopts synchronous belt pulley transmission to reduce data stretching and deformation.The side door oven and the film-piercing operation platform make the operators easy to work.

7.Pur laminating machine---The tension of the two ends of the traction steel roller is controlled by the floating swing arm.

8.Pur laminating machine automatic metering speed control installation.

9.Correction adopts EPC edge machine, for the purpose of pur laminating machine data collection.

10.The retracting shaft adopts the key type air expansion shaft, which is convenient for the loading and unloading of the pur laminating machine.

Copyright © Guangzhou Tiege Woodworking Machinery Co., Ltd. All Rights Reserved.| Sitemap